Automated Carousel Systems

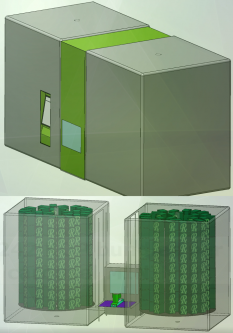

PS1000 – Prescription Fulfillment System

Designed to fit within any standard doorway, the PS1000 is the most feature rich high density, automated storage and retrieval solution in the market. Maximize the storage of any medication product – not just stock bottles! This rotary carousel will bring the product to your staff so they never have to walk up and down the aisles again. With a multitude of configurable bins and bin types, the PS1000 can fill and dispense any type of medication including pre-stocked bingo cards.

Space Savings

In just 11 square feet (36″ x 42″), the PS1000 stores the equivalent of 5 to 6 racks of medications products – resulting in approximately a six to one reduction in storage space.

Labor Savings

The PS1000 averages a 5 second retrieval time. This results in the ability to pick and stick up to 240 items per hour – depending on the type of prescription and how it is packed out. For many pharmacies, this can be a 400% improvement in current fill rates which means you can fill more prescriptions with the same or less staff or redeploy that staff to other revenue generating tasks. Our workflow also creates opportunities for pharmacist labor reduction on prescriptions processed through our systems.

Inventory Savings

The PS1000 is a complete, high density, inventory management system. Using our integrated reordering processes, real time inventory monitoring and prioritized replenishment methods pharmacies can reduce the days supply they traditionally keep on hand, reduce the amount of expired meds as well as diversion, waste and other loss.

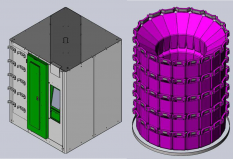

PS2000 – Prescription Fulfillment System

The PS2000 is simply a larger (2.4X) version of the PS1000 system. The PS2000 packs all the features and benefits of its smaller version. The PS2000 is larger which requires a dock door and adequate pathway through the facility. Typically used for special applications, larger form factored product or larger stocking volumes, this rotary carousel supports the processing of any type of prescription, including pre-stocked bingo cards. The PS2000 bins are different than the PS1000 but are still configurable to be customized to particular pharmacy’s requirements.

Space Savings

In just 26.5 square feet (62″ x 62″), the PS2000 stores the equivalent of 12 to 15 racks of medications products – resulting in approximately a thirteen to one reduction in storage space.

Labor Savings

The PS2000 averages a 7.5 second retrieval time. This results in the ability to process up to 200 items per hour – depending on the type of prescription and how it is packed out. For many pharmacies, this can be a 350% improvement in current fill rates which means you can fill more prescriptions with the same or less staff or redeploy that staff to other revenue generating tasks. Our workflow also creates opportunities for pharmacist labor reduction on prescriptions processed through our systems.

Inventory Savings

The PS2000 is a complete, high density, inventory management system. Using our integrated reordering processes, real time inventory monitoring and prioritized replenishment methods, pharmacies can reduce the days supply they traditionally keep on hand, reduce the amount of expired meds as well as diversion, waste and other loss.

RS1000 – Replenishment System

Keep your oral solid packaging technology replenished and running more consistently with the RS1000. Refill canisters and prepare medications for tray filling more quickly and efficiently with the RS1000 placed directly next the packaging automation.

Space Savings

In just 11 square feet (36″ x 42″), the PS1000 stores the equivalent of 5 to 6 racks of medications products – resulting in approximately a six to one reduction in storage space. Depending on the wholesalers used, one can anticipate approximately 500 SKU’s and 2500 stock bottles in this dense space.

Increase Capacity

Every minute you spend replenishing canisters or searching for product to fill trays is lost capacity. The RS1000 can cut that downtime in half resulting in two things. First, this reduces the labor hours on the machine by enabling you to service your current volume more efficiently. Second, by keeping your automation running more smoothly, you will delay any further investment since you can add more patient volume to your existing system.

Inventory Savings

Reduce the number of redundant inventory locations, especially for those expensive medications, with the RS1000. Besides keeping the inventory adjacent to your automation, you can control the number of open bottles and reduce waste, loss and diversion.

CS1000 – Controlled Substance System

Depending on your objective, bring controls out of the traditional cage safely and effectively with the CS1000 or optimize your operation within an existing controls cage. The CS1000 can be configured to store any form of controlled medication including 6″ x 9″ bingo cards as well as 3″ x 9″ stick pack cards.

As with all Accutrieve 1000 series carousels, the CS1000 limits access to CII’s as well as CIII’s through CV’s.

Security

As with all Accutrieve 1000 series carousels, the CS1000 is an all steel constructed machine. The large steel main door consists of two keyed locks under pharmacist control. The front steel night door can be electronically locked at the end of operation, end of shift or end of day. Behind the night door are two bidirectional steel tambours that travel and only provide access to the bin where medication is being retrieved from. With the average pharmacy theft occurring in 5 minutes or less, the CS1000 keeps your controlled substances safe and secure.

Space Savings

In just 11 square feet (36″ x 42″), the CS1000 stores the equivalent of 5 to 6 racks of medications products – resulting in approximately a six to one reduction in storage space.

Labor and Inventory Savings

Besides the fast index time and consolidate workflow steps, the CS1000 can reduce the amount of labor required for inventory management and reconciliation through its workflow and reducing inventory variation. Explore our unique daily audit feature allowing you to “play back” all of the transactions processed for a given day, between a specific period of time.

IK1000/IK2000 – Inventory Kitting System

The IK1000 / IK2000 simplifies fulfillment operations for the restocking of any type of automated dispensing cabinets (ADC’s) or other product bundling need. It supports the checking in or consumption intake generating the fill demand to replenish cabinets or kits on whatever periodicity you service the customer. Accutrieve’s Inventory Kitting System is available in either the 1000 series carousel or the 2000 series carousel. We work with you closely to solution the best carousel for your particular operation and they types of products being handled.

Space Savings

The Inventory Kitting System leverages the density afforded by either carousel series. Store your unit dose and other loose pieces or parts in our unique bin in bin (BIB) system. Traditionally, a large amount of space is ineffectively used with one sized, plastic bins, stored in an industrial cabinet. The IK1000 or IK2000 bins are assigned by the maximum volume by product. This creates an extremely dense storage solution.

Labor Savings

Stop trying to restock ADC’s or other product bundling operations from stacks of paper reports and a box of BIC pens. The IK1000 / 1K2000 can integrate the loading of both the consumption data and order data to automatically generate picking batches to refill the restock containers – quickly and efficiently. Similar to all of Accutrieve’s workflow solutions, our consolidated workflow steps reduce the number of touches your staff needs to make to complete these tasks.

Inventory Savings

In addition to all the standard inventory management features, if your operation supports returns, salvage that inventory with our serial, lot and/or expiration date tracking. The IK1000 and IK2000 can consume specific inventory first, reducing the risk of going out of date before consumption or use.

FD1000 – In-Facility Dispensing System

Designed to go through any standard doorway, the FD1000 is your high density solution for storing and retrieve inventory in the facilities your pharmacy services. Most automated dispensing cabinets provide a depth of inventory (typically 10 doses) versus breadth of inventory (typically limited to 200 SKU’s or less). The access to a bin holding multiple doses promotes diversion. The FD1000 is the ideal first dose solution as it eliminates this risk by providing access to single doses of medications across over 2000 bin locations. The FD1000 can also be configured to store pre-labeled medications for dispensing of larger quantities than just unit dose.

Revenue Savings

Reduce losses associated to transferring prescriptions for emergency fills because your traditional ADC doesn’t hold the medication required for that late admission or last minute change in strength or dosage.

Increase Retention

Many facilities look at medication availability (or fines based upon this in certain states) as metric during contract renewal time. The FD1000 can help ensure that lack of medication availability or late administration waiting on a delivery become a thing of the past. The FD1000 can enable your pharmacy to keep facilities using the system retained.

RP1000 – Remote Pharmacy System

Supporting any type of pharmacy servicing assisted living styled facilities or campuses, the RP1000 can be used to service those residents as well as promote growth of contracting other residents by being the only pharmacy with an onsite presence. Our small footprint supports deployment in small, existing facility spaces (closet / office). Brand your pharmacy outside this space and the residents will question why they are being serviced by a delivery pharmacy versus one that can fill their prescription onsite – immediately after a prescriber visit.

Space Savings

As with all the 1000 series carousels, the RP1000 occupies just 11 square feet. Configure the RP1000 to automatically store and retrieve any type of form factor for the medications dispensed in said facility based on the acuity level of the residents served. Any carousel can be configured for multiple types of medications.

Revenue Growth

Imagine the opportunity to be the only pharmacy with an onsite presence to service the residents. Many pharmacies only gain 20% to 30% of the facility population. With the RP1000, your pharmacy can boast incredible census gains of 80% or higher.

WC1000 – Will Call System

Designed for the retail market, consider the scalable WC1000 as a standalone system or integrate it with any of Accutrieve’s automated prescription fulfillment carousels (e.g. PS1000). Stop dealing with small, dimly lit LED’s or half your existing system going down because of battery failure.

Simply dispense the prescription(s) for a given patient and associate those prescriptions to a will call container barcode. The WC1000 automatically assigns and tracks these prescriptions to its container and storage location.

When the patient arrives at the counter (or via drive through) simply select by patient or prescription number and the WC1000 will automatically retrieve and present the patient’s will call container. After scanning container out of the WC1000 system, the container can be reassigned to the next patient.

Improve Compliance

Eliminate any risk of handout error with the WC1000’s barcode verification process. The WC1000 manages whether a container is assigned or unassigned as well as ensures only a given patient’s medications are within a given container. Because we take optical verification needs away, minimize visible PHI by increasing the opacity of the container. The WC1000 also manages your return to stock process from abandoned prescriptions. Simply run Accutrieve’s Aged Will Call batch and all the returns can be removed from the machine at once.

Improve Patient Experience

Like other 1000 series carousels, retrieve a will call container within 5 seconds on average. This ability will significantly reduce patient wait times by upwards of 80% to 90%. Your patient’s will no longer watch your staff hunt and find misplaced prescriptions. Now that the WC1000 brings the patient medications to your staff, they have the ability to spend more quality time with your patients at the counter, improving interactions, care and outcomes. The WC1000 can interface with other text messaging services to provide notifications once assigned to a will call container.

Improve Efficiency

As with all of Accutrieve’s solutions, you no longer need to alphabetize the storage of your patient medications. The WC1000 dynamically assigns will call containers and storage locations to maximize process efficiency. Labor hours may be reduced as wasted time finding prescriptions is eliminated. With the WC1000’s scalable, rotary storage method the floor space for your retail or outpatient space is better utilized as walk time becomes a thing of the past. In process inventory can also be secured at the end of shift or end of day – preventing that inventory from being stolen.

KP242/350/484 – Keep On Person System

Pharmacist, nursing staff and correctional officer labor costs are increasing dramatically in correctional facilities as well as everywhere else. For certain medications (mostly OTC’s) that are allowed to be self administered or stored within a cell, Accutrieve’s Keep On Person (KP) systems track stocked inventory, inmate census and permissions by cell or pod as well as inmate consumption data, reporting and analysis.

Local or Central Solutions

Depending on census, SKU’s and other requirements, Accutrieve provides two types of KP systems – local (i.e. a small unit in each pod) or central (i.e. larger, fully automated unit in central location). KP350 is a local solution and designed to be placed into each pod.

The inmate scans their identification. The system checks for eligibility and the inmate makes their choice of product based on their need. The KP242/KP484 is a scalable, fully automated solution where bins of patient specific medications and PRN OTC medications from the pharmacy are automatically loaded and stored in the carousel(s).

Upon scanning and verifying an inmate’s identification, medication bins are presented to a patient portal. If only one carousel is required a KP242 is solutioned. If more bins are required, a KP484 is solutioned.

Savings Opportunities

Depending on the number of SKU’s targeting to be dispensed and the number of inmates being serviced per pod or central location, the KP system typically pays itself back in a matter of months based on the average cost to dispense a pack of medication. Other savings opportunities are found withing inventory management improvements as well as overall administration of these type of programs

SC2000 – Stage/Sorting Carousel System

Accutrieve’s staging and sorting carousel system enables LTC pharmacies to rethink how they process their prescriptions – from the beginning to the end of the process. Using the SC2000 with other Accutrieve technologies, approximately 80% of all prescriptions can be presorted direct to the delivery point.

Operators can bring single items, presorted totes or mixed totes. The SC2000 knows how the totes are sorted and prompts the operator accordingly. If scanning totes, the operators can run in either verify mode or transfer mode.

Verify mode is used when a pharmacy may not have good tote control and/or it is desired to verify each item as transferred into the delivery container.

Transfer mode is used with disciplined pharmacies where the SC2000 presents the sort location and the operator simply has to dump the contents into the delivery container. Upon closing the manifest, the system prints bag labels and manifest documents. Closing can be achieved by facility, facility unit, routes or runs – eliminating the need for couriers to wonder searching for all their bags.

Space Savings

Although configurable as to the total number of bags per carousel based on bag length, the standard SC2000 carousel holds one hundred 14″ x 27″ poly bags. This equates to 35 linear feet of traditional racking resulting in a 7 fold reduction of linear feet – a major impact to walk times. As with the other 2000 series carousels, the SC2000 does all that it does in just 26.5 square feet.

Labor Savings

With a 7.5 second index, the SC2000 sorts with scan verification 8 individual items per minute. Combined with our work to tote solutions with an average of 10 items per tote, in Transfer Mode, that is equivalent to approximately 70 items sorted and staged per minute. In Verify Mode, that is equivalent to approximately 50 items sorted and staged per minute. Pharmacies with over 10,000 items sorted per day are experiencing labor reductions of over 50%.

Eliminate Revenue Loss

Every mis-sort seems to be a double-whammy. First, the facility getting the medication in error never returns that $1250 card of product. Second, you now have to expedite the delivery of the prescription for the facility in which it was intended. Not to mention the lack of withdrawing a discontinued medication prior to leaving the pharmacy.

The SC2000 takes care of all of these nuances for you. Upon each scan of an item or each scan of a tote containing items, each prescription is re-checked to make sure it has not been discontinued, flagged or cancelled in some manner. If a prescription is marked, the operator will be prompted to scan that item out of the tote or delivery container prior to manifest close.

Fill More Scripts

Quickly & More Accurately

Reducing Labor Hours

Becoming More Efficient

While Saving Space

Partner with a technology company that delivers results!

We may specialize in PHARMACY, but our technologies readily transfer to your industry as well:

- Boxed Subscription Services

- High Value Item Dispensing

- Controlled / Hazardous Materials

- Unattended Retailing / Kiosk

- Warehouse / Pick Pack Ship

- Kitting / Assembly

- Manufacturing